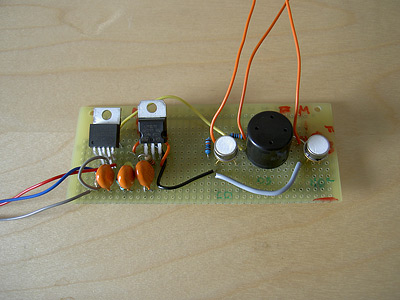

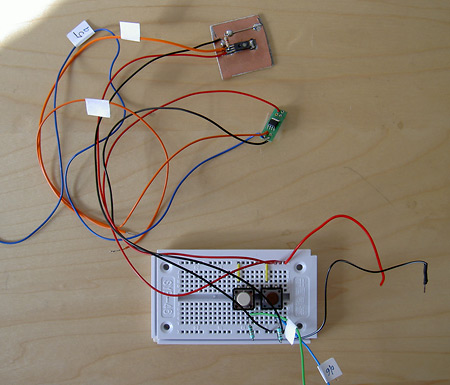

On the photograph you can see the 5 volt circuit. It houses two sensors and two buttons. At the workshop last Saturday I put together button circuit, if you press the white one it means it smells good, the brown one indicates it smells bad. This is of course just a functional setup, purely for testing hardware and code. Later I’ll make soft buttons which will be integrated in the vest. We also made the humidity sensor (the kinky copper plate, we ran out of circuit board.) It will take some time to calculate the actual humidity from the output and before I can use it with the ozone sensor. A period of extensive callibration is due anyway.

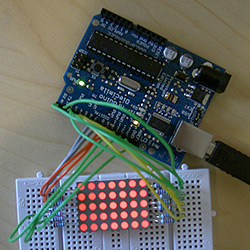

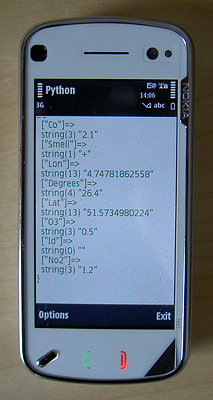

I worked on the code which I completed today. The Arduino now collects data from all sensors (except the gas sensors which somehow have stopped working at the moment) and outputs an ‘e’ when no buttons was pressed, a ‘+’ when the smells good button was pressed and a ‘-’ when the bad button was pressed. It works in a two minute loop which is broken when a button is pressed, then data is immediately collected and send.

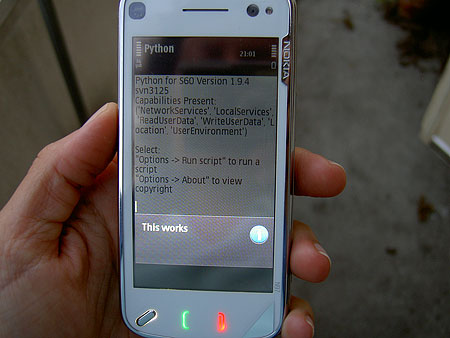

As for the sending part, I’m still working on the Bluetooth connection between the Arduino and the phone.

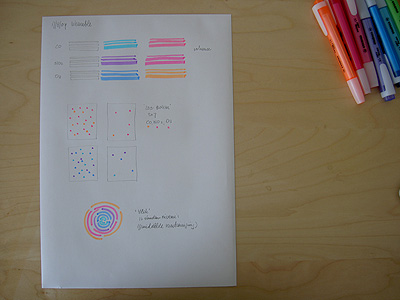

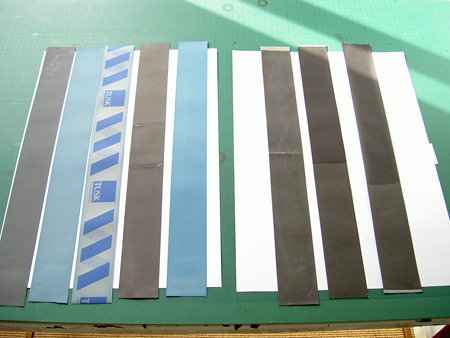

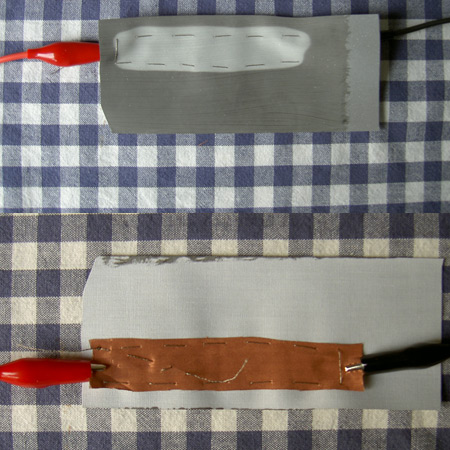

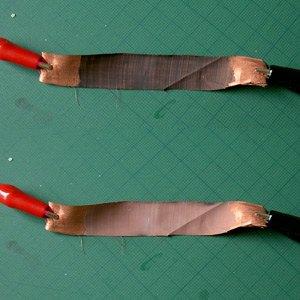

I had a brainwave and realized that I could also use silver conductive fabric for the strips if things don’t work out with the retroreflective material. The copper fabric gives excellent results when painted with the thermochromic ink.

I had a brainwave and realized that I could also use silver conductive fabric for the strips if things don’t work out with the retroreflective material. The copper fabric gives excellent results when painted with the thermochromic ink.