I’m having a hard time with my wearable. There are different areas where I’m experiencing problems:

– The thermochromic ink deteriorates very fast. Under influence of UV radiation for which I haven’t been able to find a solution. The amount of electricity it needs to heat up is very much depending on the air temperature. Also the width of the strip of fabric (this has to be equal for the whole length) is crucial for successful colour change. So there’s a lot of testing ahead before this will work well. I have switched from reflective strip to using reflective fabric, I wonder if the performance will improve.

– I’ve been talking to a lot of experts lately but Friday last I got a pretty disturbing e-mail from the RIVM which is a leading Dutch centre of expertise and research, it advises and supports policy-makers and professionals in public health and environmental areas. The gases I’m measuring are a good indication of air quality but the sensors I’m using aren’t sensitive enough. I was happy to find gas sensors in the first place but now they appear to be worthless for my purpose.

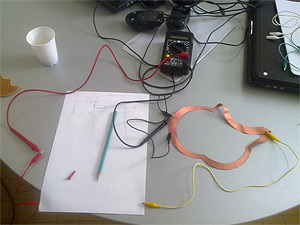

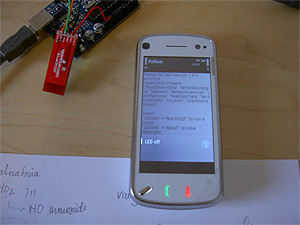

– Programming the Bluetooth connection has made some progress. I can now connect with the Arduino board and send and receive bytes. Now I’m at the final stage of sending all of my sensor data in a single string to the Nokia. I also have to find out how to let Python check for incoming serial data continuously. Some sort of event listener.

– I keep having trouble using the internal GPS. It seems to break down after I’ve used it once. Only a restart will make it work again.

– On the bright side I’ve made two dummies for my vest. Saturday I worked together with my tailor on my second dummy, using the actual fabric. This gave me a lot of insight in what I want. Discussing it with AnnaMariaCornelia it became clear that I have to take a radical turn to make my vest look like true work ware. I’m really looking forward to designing my vest and make it look sturdy and cool to wear.